3D Gingery Machines

Update: 2010-06-04

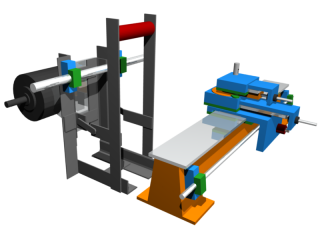

The motor supports and counter shaft are now roughed in. This stage helped me learn a bit about how the pulley-switching mechanism will work. I will be working on the complex pulley models next.

Update: 2010-06-03

The tool rest assembly is one complex bit of machinery. I'm still roughing in the objects, but got a bit done today.

Posted: 2010-06-02

After beginning my foray into the world of hobby machining, I discovered the Gingery series of books describing how to construct a complete machine shop, essentially trading your time for money. While it isn't yet my intention to build a whole shop from scratch (my priorities might change in that direction, however), I have been inspired to build, at the very least, the charcoal foundry to assist in recycling valuable metals for my projects.

Even if I do purchase some of my own machine tools in the future (probably the Sieg-manufactured mini lathe [SC2] and mini mill [SX2]), I am very interested in building the Gingery lathe both as a learning experience, and a way to have a larger lathe for very little monetary investment.

While reading through the Gingery lathe book, I find myself wondering about the systems-level decisions in its design. The book is great about describing how to build the lathe, but it doesn't go into the reasons for some of the details in each part. I believe Mr. Gingery intended this to be an exercise for the student machinist to discover on their own as they build the lathe.

Also, I'm an engineer. Before I even push a wire into a breadboard, open a source code file, or start cutting a part, I need to have an idea of the entire system. I'd like to know where the tolerances are critical, and where there is some wiggle room. I need to know if I make a small change to the design to suit my situation (lack of a tool, cheaper material, etc), how it will affect the operation of the overall machine. Or, better yet, if I spend an extra couple of dollars on material, I might be able to improve the design and build a better, high-capacity machine.

To this end, I've started a little project in my random moments of spare computer time to model the Gingery lathe (and hopefully the other machines) in Blender 3D. This is mostly an exercise for myself, but there might just be a prospective machinist out there who might find my models useful in working on their own project.

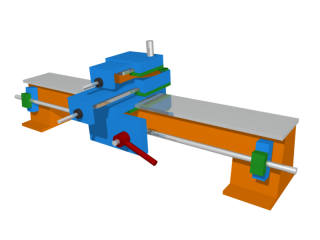

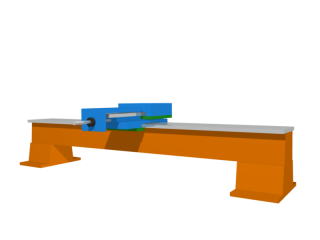

Right now, I've just begun a few of the basic parts. The render shown includes the bases, bed, way, carriage, and cross slide. I haven't even started on the fasteners yet, and I've left out the gibs until I've finished the model. The materials are just roughed-in to provide some contrast between the parts. After a little more progress, I'll start posting the .blend file for anyone to pull apart.

If I find myself really bored on a rainy afternoon, I might even work in some animation controls so a person could move the parts of the lathe around using parametric inputs.